Hatz 4H50TIC world premiere

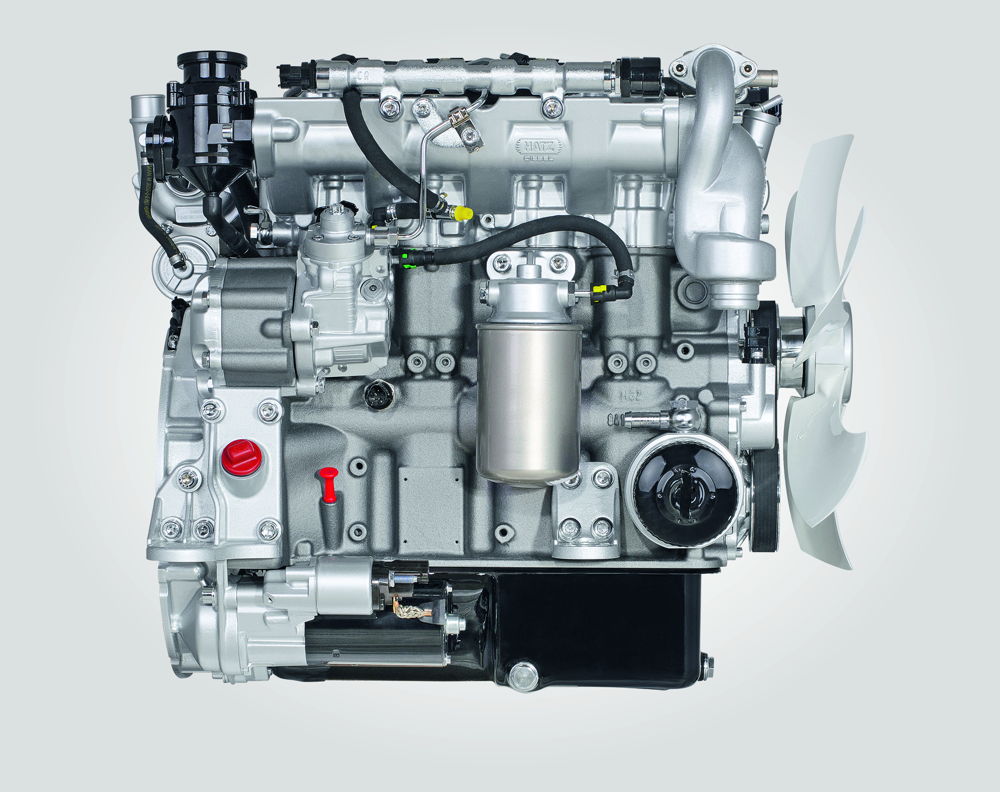

At this year's Bauma in Munich Hatz Diesel unveils the first engine of a newly developed water-cooled engine series. The 2-liter turbo engine sets new standards in its class in terms of fuel efficiency, power density and robustness

8 April 2013

A new engine family will expand the portfolio of the Motorenfabrik Hatz, which is celebrating its world premiere with the presentation of the 4-cylinder version at the Bauma 2013.

The launch of the 2-liter diesel engine, which is equipped with a Bosch common rail injection system, turbocharger and external exhaust gas recirculation, will be in spring 2014. Like all Hatz engines, this engine also brings a number of technical refinements with it, which leads to the fact that the engine is the most compact in its class, and has the best fuel efficiency in comparison to competitiors.

Downsizing approach

When developing the 4H50TIC, a ground-breaking downsizing approach was followed. The primary development goals were the reduction of size and weight combined with high performance and good exhaust gas values. The result is a turbocharged 2-liter engine which achieves a maximum output of 55kW. With a weight of 173kg it is the benchmark in its class. The engine meets the strict limits of the 97/68/EC Stage IIIB and EPA Tier 4 final without a particulate filter.

The engine crankcase is made of a thin-wall cast iron, the cylinder head and valve cover made of cast aluminum and the oil sump of steel. All parts are optimized in terms of weight and structural mechanics.

Conservative-innovative engine design for long engine life

All mechanical components have been developed with a conservative but yet innovative approach. The 4H50TIC is equipped with two valves per cylinder, whereby a high efficiency, mechanical robustness and functional simplicity has been achieved. This leads in turn to the well-known robustness of Hatz products. Despite some principle related thermodynamic disadvantages of the chosen 2-valve technology in comparison to multi-valve technology, emission values are achieved, which significantly fall below the requirements of the 97/68/EC and EPA, Mainly because of optimized piston bowl and injection technology.

According to the Hatz quality standards, the selection of suppliers has been made: For all essential parts of the engine such as fuel injection, crankcase, crankshaft, camshaft, exhaust gas recirculation valve, catalyst and sensors, the company has opted for premium products from reputable suppliers which mostly come from Germany.

Bosch common rail system for maximum fuel efficiency

One of the key factors contributing to the high power density of the 4H50TIC is the Bosch Off-Highway common rail system with 1800 bars, which is used for the first time in industrial diesel engines. In this case the system works with three injections per working cycle; a pre-, main-and post-injection. By that the perfect balance between durability, quiet combustion noise and excellent emission values is reached.

In terms of fuel efficiency, the new engine sets new standards with a specific fuel consumption of just 210 g / kWh at the best point. The speciality is that the low fuel consumption is achieved in a wide load and speed range. This makes the 4H50TIC the most efficient engine in the class from 37 to 56 kW.

Combustion strategy and turbocharger

In order to reduce the thermal burden on the exhaust gas recirculation system, a number of innovative measures were designed: For example, a pre-cooling unit for exhaust gas recirculation, which cools the hot exhaust gases considerably before the EGR valve and thus simultaneously protects the valve against thermal damage and sooting. Further a optimized EGR mixing nozzle is used, which helps the recirculated exhaust gases to be evenly distributed with the fresh combustion air to all four cylinders. Together with the already mentioned injection technology, therefore, a very good exhaust quality can be achieved, which ensures that the 4H50TIC is equipped only with an oxidation catalyst. The engine falls significantly below the emission limits of the 97/68/EC and EPA even without the use of a particulate filter.

Special attention was paid to the best compromise between response, maximum power, and generally high efficiency over the entire speed range during the matching of the wastegate turbocharger.

Internal friction

Another key to the extremely high fuel efficiency is the reduction of internal friction, which could be achieved because of the conservative design with very few moving parts. The 2-valve technology with roller tappets and the camshaft in block bear a substantial share of this. In addition, for connecting rod bearings and only high-end materials have been used.

Serviceability

With a service interval of 500 hours, the engine also scores in terms of customer service. The extended intervals are achieved because of a hydraulic valve adjustment and well dimensioned fuel filter. In addition, the engine is equipped with an engine protection system based on various sensors. In case of significant engine failures the engine shuts off in order to prevent capital damages.

Technical data

|

4H50TIC |

||

|

Cylinders |

4 |

|

|

Displacement [ccm] |

1,952 |

|

|

Valves per cylinder |

2 |

|

|

F power [kW/PS] |

55,4/75,3 |

2600 min-1 |

|

55,4/75,3 |

2800 min-1 |

|

|

IFN power [kW/PS] |

45,9/62,4 |

2300 min-1 |

|

51,3/69,8 |

2600 min-1 |

|

|

55/74,8 |

2800 min-1 |

|

|

Power generator set IFN [kW/PS] |

28,7/39,0 |

1500 min-1 |

|

36,9/50,2 |

1800 min-1 |

|

|

48/65,3 |

3000 min-1 |

|

|

combustion |

Direct injection, turbo charged, intercooler and external cooled EGR |

|

|

Injection system |

Bosch Common Rail OHW, max. 1800 bar |

|

|

Compression ratio |

17,5:1 |

|

|

Lower idle speed[rpm] |

900 |

|

|

Maximum speed (idle) [rpm] |

3300 |

|

|

max. torque [Nm@rpm] |

240,0@1600 |

|

|

Weight [kg] |

173 |

|

|

Cooling system |

Water cooling |

|

|

Best fuel consumption [g/kWh] |

210 |

|

|

Emission level |

EU 97/68 Stage IIIB, US EPA TIER IV final |

|

|

Exhaust aftertreatment |

Oxidation catalyst |

|

The new Hatz 4H50TIC sets new standards in the power range up to 56 kW. The extremely compact diesel engine impresses with its high power density and requires no DPF.

The new Hatz 4H50TIC sets new standards in the power range up to 56 kW. The extremely compact diesel engine impresses with its high power density and requires no DPF. The new Hatz 4H50TIC is equipped with a BOSCH Common-Rail Off-Highway system. With 210 g / kWh (bestpoint) the engine is very fuel efficient.

The new Hatz 4H50TIC is equipped with a BOSCH Common-Rail Off-Highway system. With 210 g / kWh (bestpoint) the engine is very fuel efficient.