Hatz première at Intermat 2018 with new EU Stage V engine and online services

At the Hatz trade fair stand in Intermat 2018 the focus is on the latest H-series engine generation for EU Stage V and Hatz Smart Parts.

18 January 2018

Motorenfabrik Hatz will showcase the new H-series three-cylinder diesel engine the Hatz 3H50T for the first time from 23 to 28 April 2018 at Intermat in Paris.

The engines developed according to the rightsizing principle are characterised by their small sizes, low weight, with high performance and power at low speeds. The H-series engine generation is predestined for operation in compliance with the EU Stage V emission standard. It provides machine manufacturers with the latest alternatives to upgrade existing machines with the smallest design adaptations, and to make new machines sustainable with conservative-innovative technology. Furthermore, Hatz will present the new Smart Parts programme which makes it considerably easier for partners and customers to identify and purchase maintenance and spare parts. Hatz can be found at Intermat in Hall 5a at Stand E 002.

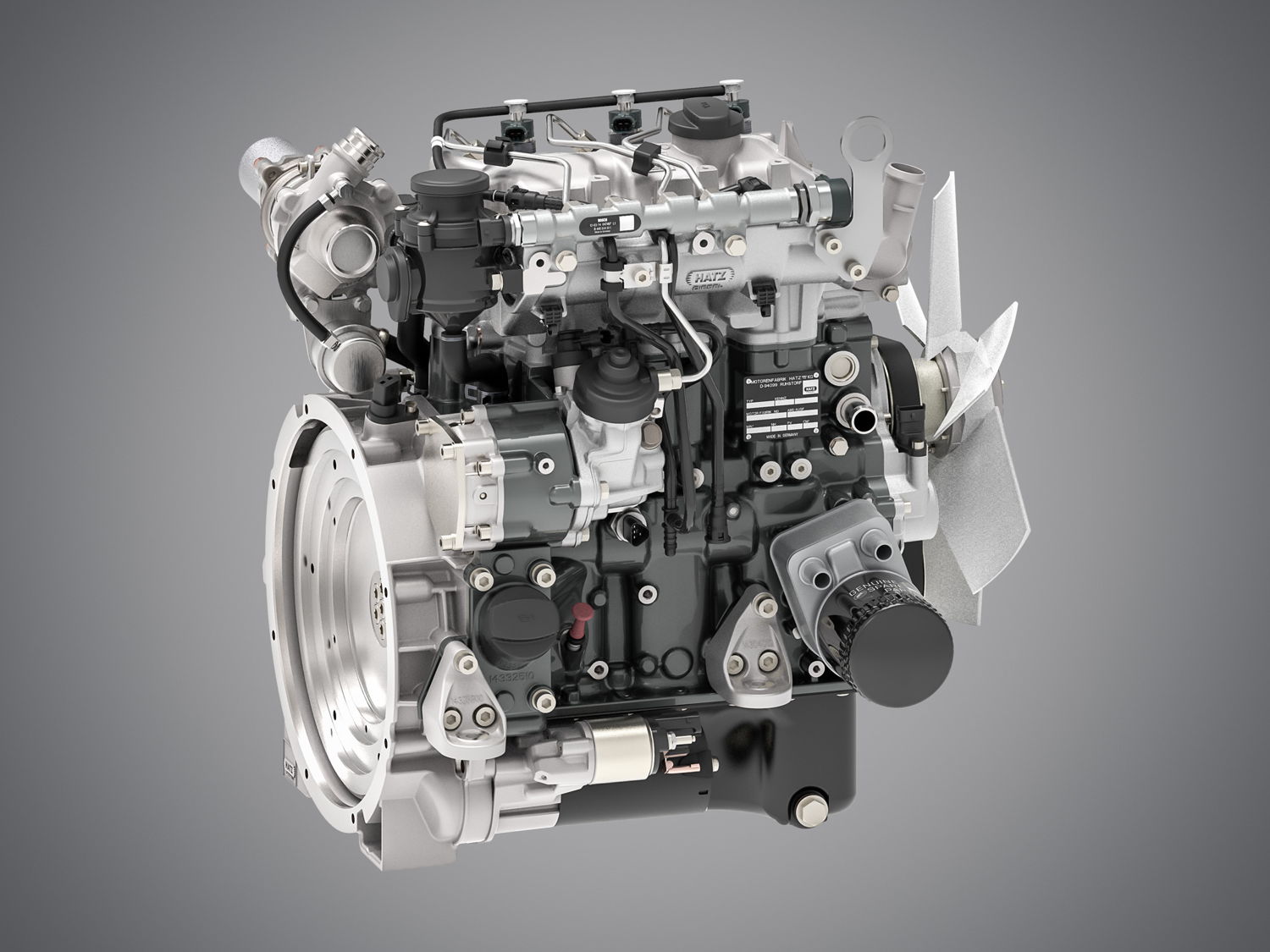

New powerful three-cylinder Hatz 3H50T

At around the same time as the official market launch of the three-cylinder engines in its H-series, for the first time Hatz will showcase to Intermat visitors a further diesel engine from this category, the new Hatz 3H50T. The liquid-cooled three-cylinder extends the product range of the latest engine family that was developed specially for high demands on power, performance and reliability, as well as for use in compliance with the strict EU Stage V emission standard. The version with a maximum output of 18.4 kilowatts effortlessly achieves this emission requirement without any exhaust emission after-treatment – such as diesel particulate filter (DPF), exhaust gas recirculation or diesel oxidation catalyst (DOC). The Hatz 3H50T is the engine with the highest torque in its class in the market today with a displacement of only 1.5 litres, no charge air cooler and an output of 130 Newton metres. It is therefore the ideal choice for reasonably upgrading existing machines in the 19 to 37 kilowatt class to EU Stage V, for example.

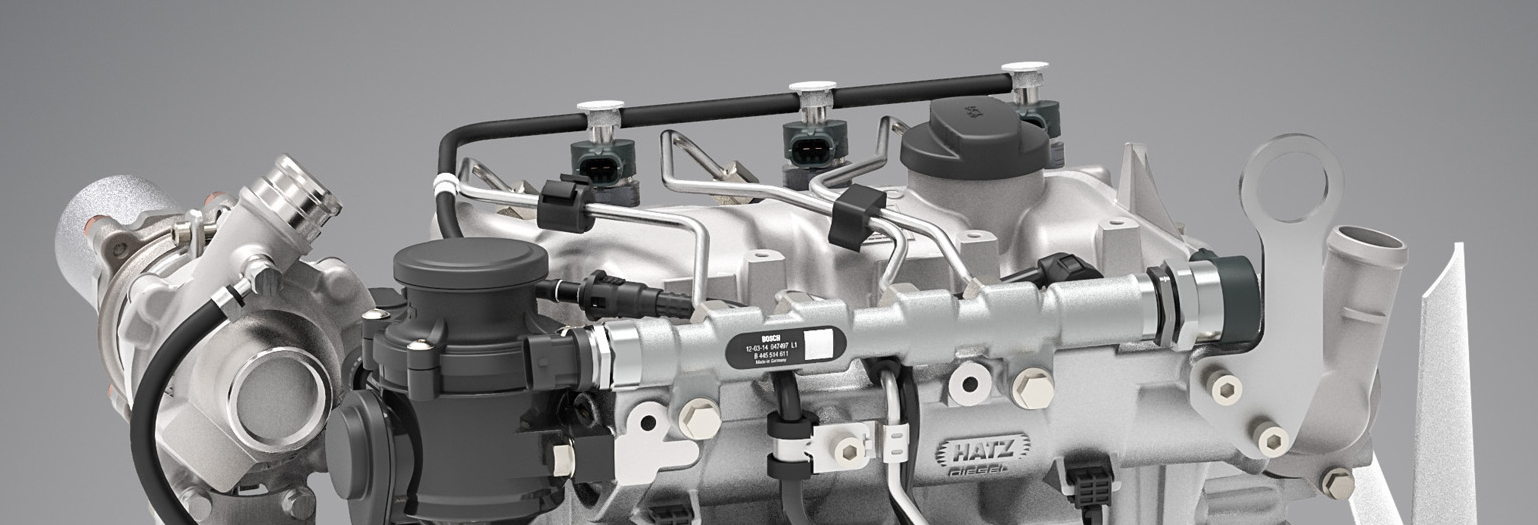

The 3H50T will also be available as an OPU (Open Power Unit) variant. With its integrated and optimal design of the radiator, hoses and cabling as well as the electronics, the Hatz OPU concept greatly simplifies design and installation for machine manufacturers. Just like the entire Hatz H-series, the rightsizing strategy has consistently been implemented for the latest three-cylinder engines: state-of-the-art materials and technologies such as turbochargers and the Bosch common rail system (off-highway version) form the basis of the compact and robust engines that feature high torque at low speed.

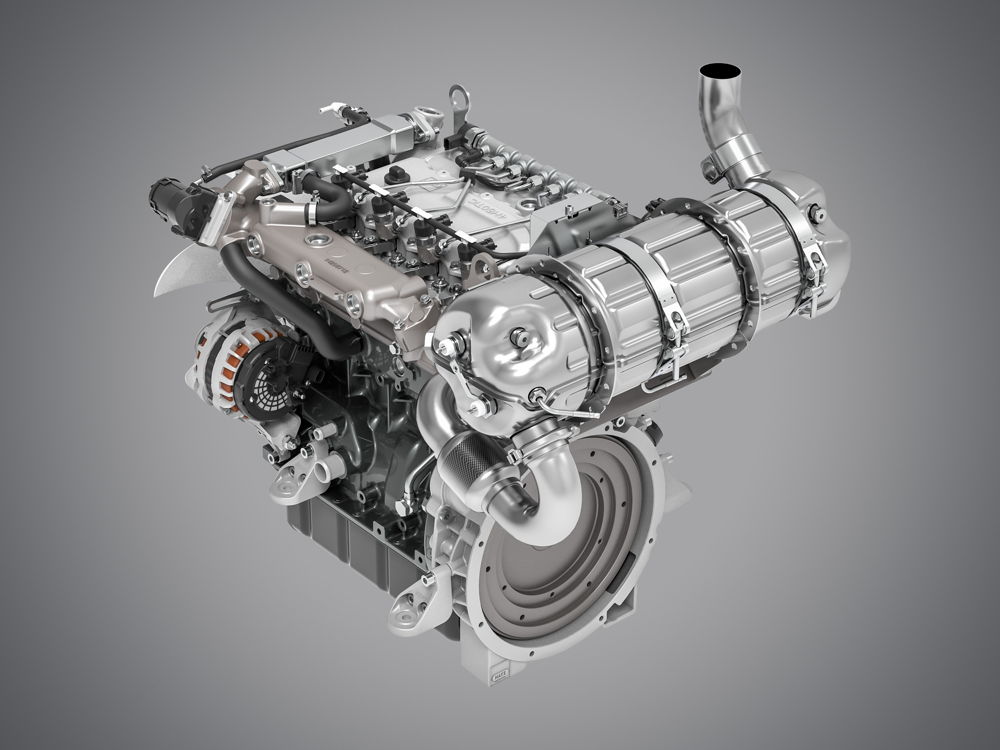

Four-cylinder 4H50TICD fully equipped for EU Stage V

The Hatz four-cylinder engine is based on the proven 4H50TIC model. It is additionally equipped with a turbocharger, intercooler and catalytic converter also with a DOC-DPF unit, and has therefore also been made for use in compliance with the EU Stage V emission stage. The DPF system is adapted optimally to the application situation with the aid of optiHEAT (optimised Hatz Exhaust Aftertreatment Technology). Its compact design lets the engine also find space in machines in which comparably strong engines with DPF cannot find space.

With a displacement of two litres the Hatz 4H50TICD features an output of 55 kilowatts at 2800 rpm and a torque of 240 newton metres over a wide speed range of 1600 to 2100 rpm. Additionally, all H-series four-cylinder engines are now equipped with a new 35-degree fan as standard. The higher air throughput enables the engine to be operated in even warmer environments without overheating. A further new feature is the additional power take off possibility on the flywheel housing. Three power take-offs will be available in the future with the new, extremely compact drive source.

Master the transition to EU Stage V with equipment manufacturers

Hatz wants to make introduction of the next exhaust legislation in 2019 as easy as possible for machine construction companies. "As engine experts, we not only offer the ideal industrial diesel engines and intelligent drive concepts, we also support manufacturers with advice and assistance in implementation", says Bernhard Richter-Schützeneder, Head of Sales and Marketing at Hatz. For example, EU Stage V is not mandatory in all application areas. On the other hand, the new requirements relate not only to engines with self-ignition. "The regulation for transition and replacement engines is a science in its own right, and it's managed differently according to the performance class", knows the Sales and Marketing boss. Information on deadlines that have to be met and other compliance factors will also be provided personally by Hatz customer advisers during Intermat 2018.

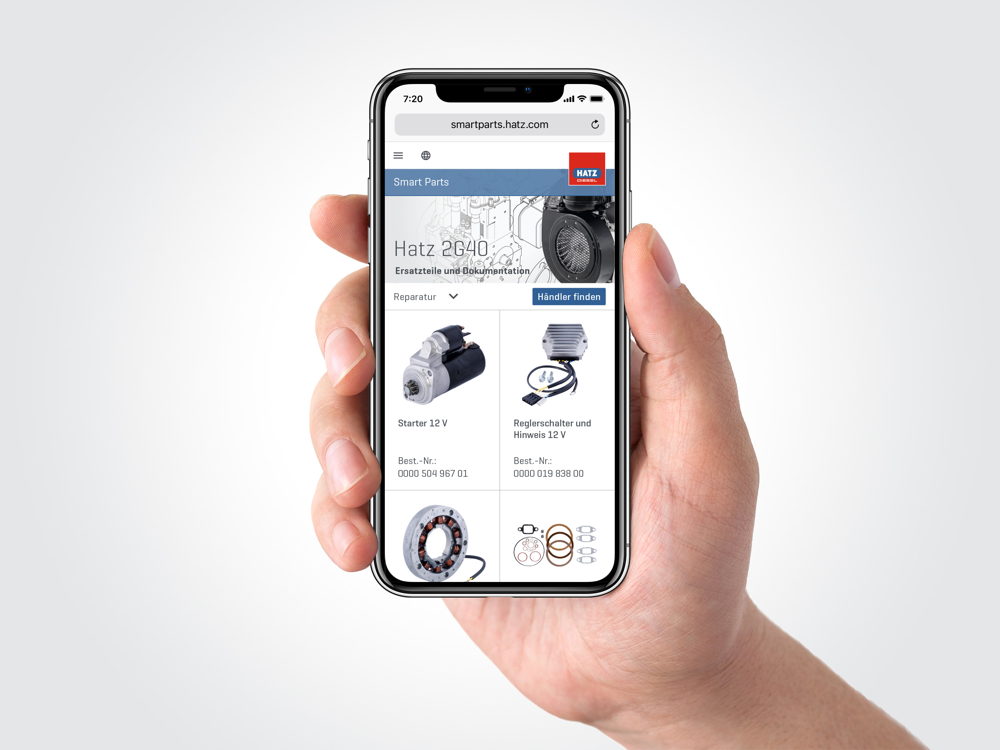

Service innovation Hatz Smart Parts

A further highlight of the trade fair is Hatz Smart Parts. Smart Parts gives customers and sales partners an intuitive online solution for searching for documents or fast identification of the right spare parts. Partners and customers only need to scan the code on the Hatz engine onto their mobile device with any QR code scanner to immediately access the appropriate web page for the Hatz engine model. Manual searching through extensive books and lists is no longer needed. With Smart Parts machine operators can find spare parts and order them from a Hatz sales partner conveniently and directly from wherever they are, such as on a construction site or in a workshop. At its launch the intelligent service will be provided for the G, L and M engine series. Smart Parts including operator's manuals with maintenance instructions is available in German, English, Spanish and French.