Innovative and Economic Diesel Technology Protects Your Health and the Environment

Hatz has always stood for innovative drive drives. Only recently, the company unveiled a series of innovations at the leading trade fair, which make the operation of engines and the machines in which they operate more economic, environmentally friendly and better for the health of the machine operators.

14 March 2023

Integrated occupational safety

Hatz recently presented its newly developed E1 DPF technology. By combining the Hatz E1 technology (electronic 1-cylinder controller) and a passive diesel particulate filter (DPF), the particle emissions of compact drives can be slashed by up to 95 percent. The integration of occupational safety in the drive system protects the health of the machine operators.

Dr. Sebastian Wohlgemuth, overall head of research and development at Hatz, explains the further advantages in machine operation: "Vibrating plate compactors and other diesel-driven compact machines fitted with the E1 DPF can be deployed more universally on the building site without breaching directives and occupational safety requirements. Moreover, the contribution to occupational safety is so high that machines with this technology are eligible for subsidy by the BG BAU (German Professional Association for the Construction Industry)."

Cutting-edge diesel technology

Hatz has already certified several of the current engines for emission-neutral or low-emission bio-diesel fuels, such as HVO. In this way, their future-proofing and environmental friendliness could once again be improved. The engine manufacturer is working towards releasing the entire drive portfolio for these forward-looking and environmentally friendly fuels.

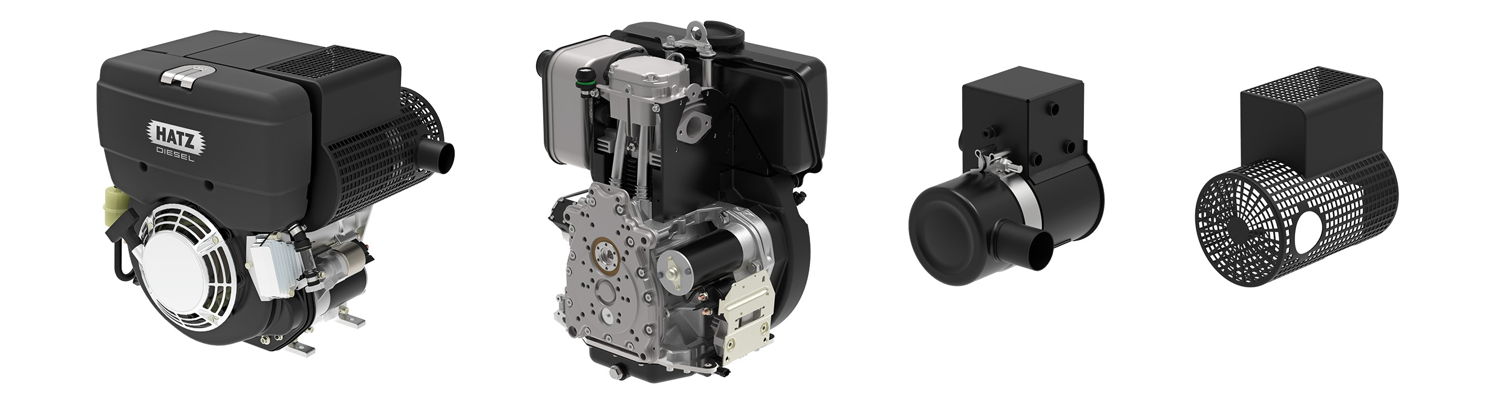

Four-cylinder engine with especially low operating costs

With the 4H50N, Hatz has developed a four-cylinder diesel engine especially for continuous operation applications. Designed as a naturally aspirated engine, maintenance intervals of 3000 hours can be realized with this engine of the Hatz H-series. This results in less downtime, lowering overall operating costs, with the low diesel consumption making a further contribution. The Hatz 4H50N will also be available as an OPU version after its market launch. These pre-mounted drive systems reduce the design and assembly effort for machine manufacturers even more significantly.