Integrated Hybrid Solutions: The Best of Both Worlds

With Hatz, construction equipment manufacturers can easily benefit from electrified system architectures without experiencing the typical limitations of electrically driven machines. The combination of compact diesel propulsion and permanent magnet generators allows machine builders to circumvent typical limitations with regard to range, number of continuous operating hours, or recharging of the electrical system.

14 March 2023

.jpg)

One way to achieve these benefits is to integrate the generator into the flywheel. The resulting permanent magnet generators, Hatz fiPMG, are suitable for use in hybrid systems, as backup against power failure, or for permanent power supply. They can also be used as range extenders in all-electric machines. Thanks to their versatility, they cover almost all application scenarios for electrified systems design.

Over 85 percent lighter and shorter than conventional generators

Engines with fiPMG technology enable longer machine operation in battery-electric drive mode, which helps to reduce emissions. Where necessary, the machine can be used with fiPMG in zero-emission operation. This reduces the load on the combustion engine and additionally protects the environment.

The extremely compact dimensions of the fiPMG minimize any necessary adjustments to the machine design. With a construction depth of 35 mm and a weight of 3 kg, the Hatz fiPMG is over 85 percent lighter and shorter than conventional generators. Thanks to the power take-off shaft, which is still available, the machine is even more flexible in terms of design. As a prefabricated and tested drive package, Hatz engines with fiPMG technology are easy for machine manufacturers to assemble and integrate. Integration into the machine’s battery charging structure is also particularly user-friendly thanks to CAN bus technology.

A particularly efficient and powerful system

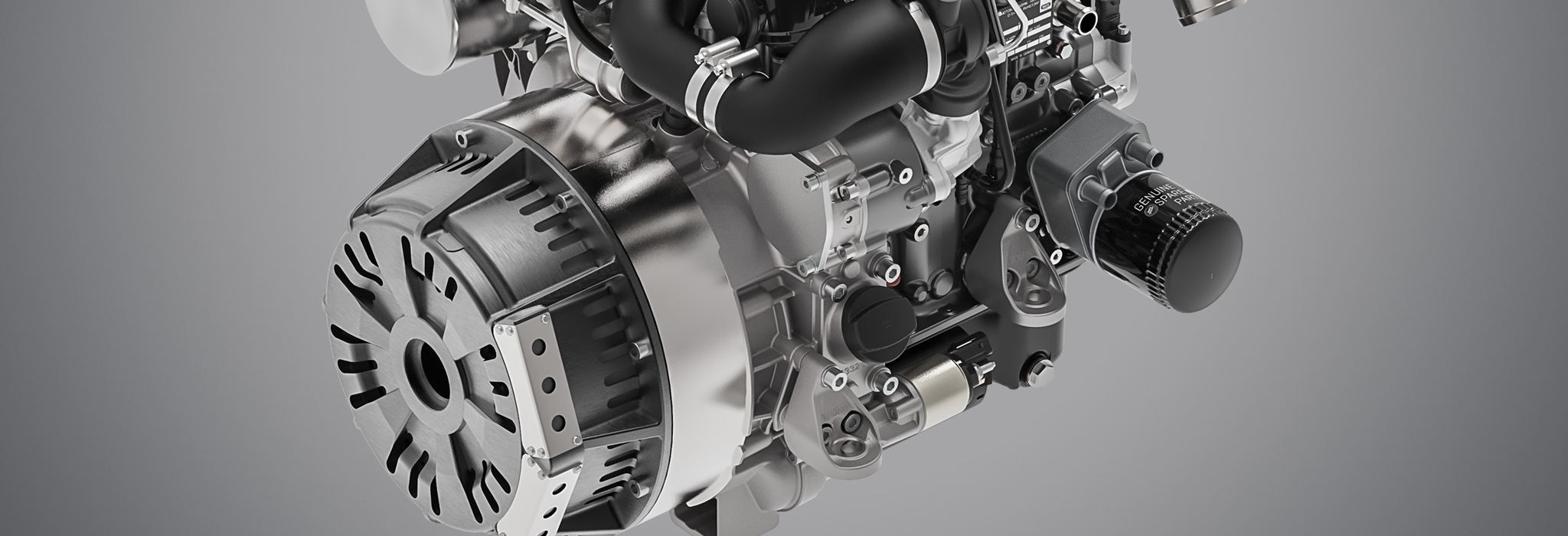

Hatz also presented the H-Series PMG concept, a powerful and at the same time highly economical hybrid solution. The drive concept was presented as a pre-assembled and pre-tested complete unit consisting of a 53 hp Hatz 3H50TIC three-cylinder diesel engine, common rail-based fuel system, control unit with all relevant sensors, and CAN bus/SAE J1939 interface as well as a 25 kW permanent magnet generator. This combination offers machine manufacturers a particularly efficient and powerful system that can be used in suitable applications with high power peaks as an economical alternative to larger engines.

.jpg)